D Nut Casting Dealer In Delhi

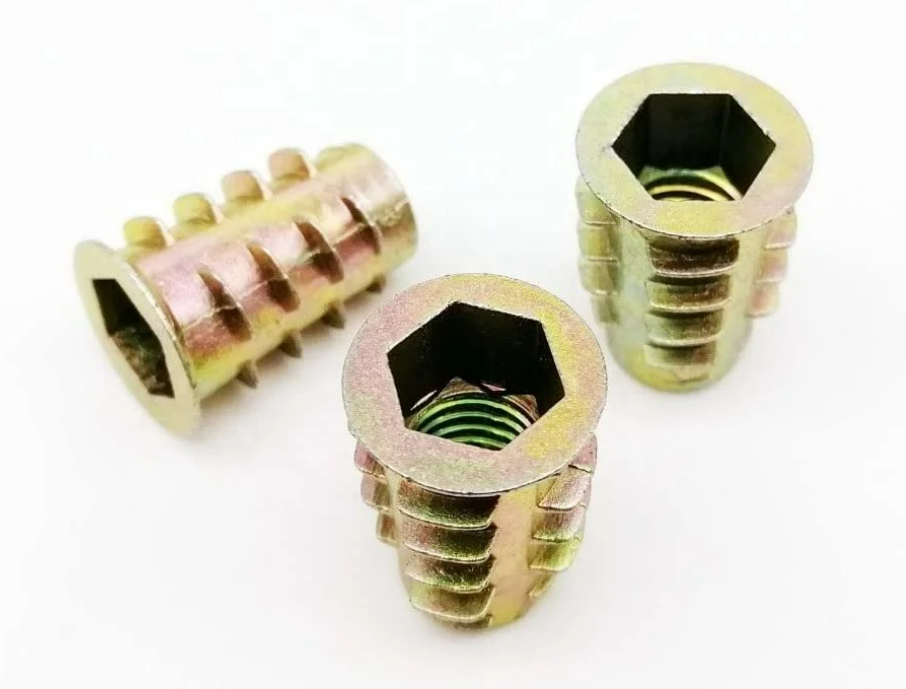

D Nut Casting refers to the process of manufacturing “D-shaped” nuts using metal casting techniques, commonly used in heavy-duty mechanical assemblies where strength, durability, and precision are essential. These nuts are named after their characteristic 'D' shape, which prevents rotation when installed in compatible slots or housings. D nuts are often used in construction, heavy machinery, automotive components, and structural applications.

The casting process involves pouring molten metal—such as cast iron, mild steel, or alloy steel—into a precisely shaped mold to form the D nut. This method ensures consistent quality, dimensional accuracy, and the ability to produce complex shapes in large quantities. Once cast, the nuts undergo machining, threading, and surface finishing to meet specific technical requirements.

D Nut Castings are especially useful in applications where access to the reverse side of a component is restricted, as they can be embedded or set into grooves and retain their position without the need for additional locking mechanisms. Their flat side resists rotation, while the threaded interior provides a strong, reusable anchor point for bolts or studs.

One of the major advantages of using cast D nuts is their load-bearing capacity. Thanks to the casting process, these components can be engineered to withstand high levels of stress and torque, making them ideal for structural frameworks, railway parts, and industrial machinery.

Additionally, the casting process allows customization of size, thread pitch, and material composition based on the specific needs of the application. This flexibility makes D Nut Casting a preferred choice for OEMs and industrial fabricators seeking reliable fastening solutions.

In conclusion, D Nut Castings are vital components in high-strength mechanical assemblies, offering performance, durability, and ease of installation. Their design and manufacturing versatility make them indispensable in modern engineering and industrial construction.

Keywords

vital components

structural applications

modern engineering

preferred choice

flexibility makes

torque making

loadbearing capacity

major advantages

threaded interior

reverse side

surface finishing

large quantities

alloy steelinto

compatible slots

prevents rotation

strength durability

casting process

nut castings

industrial construction

nut casting

manufacturing dshaped nuts

nut casting refers

nut casting dealer

industrial machinery additionally

manufacturing versatility make

material composition based

size thread pitch

withstand high levels

additional locking mechanisms

produce complex shapes

precisely shaped mold

heavyduty mechanical assemblies